Description

Table of Contents

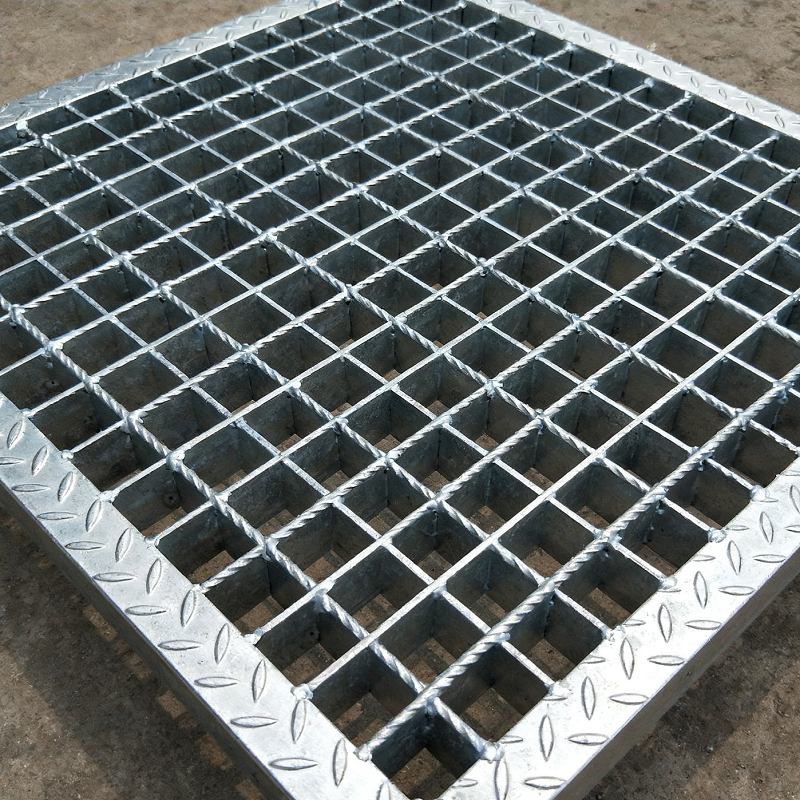

ToggleRemovable Drainage Rectangular Steel Grating Gully Metal Grid Zinc Coated Grate Cover

Product Specification

| Feature | Details |

|---|---|

| Material | Carbon steel, Stainless steel |

| Type | Flat grating, press lock grating, serrated grating |

| Bearing bar | 20mm, 25mm, 30mm,32mm,38mm, 40mm, 45mm, 50mm ect… |

| Size | as customized |

| Finish | Hot dip galvanized or polished |

1. Rectangular Steel Grating: Unique Structure for Outstanding Performance

As the core component of our product, the rectangular steel grating features a unique and sophisticated structure. It consists of a series of flat steel bars and crossbars arranged at specific intervals, firmly connected through advanced welding technology to form a regular rectangular grid. This structural design is not random but carefully engineered.

From a mechanical perspective, flat steel bars serve as the main load-bearing components. When evenly distributed, they effectively disperse pressure from above, providing stable support for the entire structure. The addition of crossbars further enhances the integrity and stability of the steel grating, enabling it to bear greater loads. For instance, in the workshop floors of heavy machinery factories, our rectangular steel gratings can easily withstand the frequent rolling of heavy equipment like forklifts, ensuring smooth production operations.

Meanwhile, this grid structure also endows the steel grating with excellent drainage and ventilation performance. In terms of drainage, rainwater or other liquids can quickly flow through the gaps of the grating, preventing water accumulation. This is particularly crucial in water-prone areas such as car washes and underground parking lots. For ventilation, good air circulation reduces issues like dampness and odors, creating a more comfortable and healthy environment.

2. Removable Steel Grating: Convenient Maintenance for High Efficiency

Our steel gratings adopt an innovative removable design, whose core concept is to provide users with more convenient and efficient maintenance experiences. In practical use, removable steel gratings demonstrate unparalleled advantages.

In municipal engineering, the city’s drainage system is like the “blood vessels” of the human body, requiring regular cleaning and maintenance to ensure normal operation. Our removable steel gratings are like convenient “inspection doors” for these “blood vessels”. Maintenance personnel only need to easily lift or remove the gratings to quickly access the inside of the gullies for inspection, cleaning, and maintenance of drainage pipes and facilities. This convenient operation greatly shortens maintenance time, improves work efficiency, and reduces impacts on urban traffic and residents’ lives. For example, during the maintenance of the drainage system on a main road in a certain city, after using our removable steel gratings, the maintenance time per session was reduced from several hours to just dozens of minutes, significantly improving the maintenance efficiency of the drainage system.

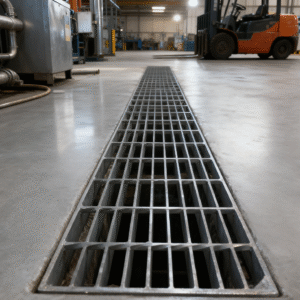

In industrial plants, removable steel gratings also play an important role. During industrial production, various debris and waste materials may enter the gullies, affecting drainage and ventilation. The easy-to-detach feature of removable steel gratings makes cleaning a breeze. Staff can open the gratings at any time to clean the debris in the gullies, ensuring smooth drainage. Additionally, for industrial equipment that requires regular inspection and maintenance, removable steel gratings provide convenient access for staff to conduct equipment overhaul and maintenance.

3. Steel Grate Grill: Versatile Applications Everywhere

Our steel grate grills, with their excellent performance and reliable quality, are widely used in numerous fields and have become an indispensable part of modern infrastructure construction.

In municipal road construction, steel grate grills are extensively used in parts such as drainage ditches and rain inlets. They not only effectively filter debris to prevent garbage from entering the drainage system and causing blockages but also ensure the rapid discharge of rainwater, avoiding road water accumulation and safeguarding the safe passage of pedestrians and vehicles. For example, on the main roads of some cities, we can see drainage ditches equipped with steel grate grills at regular intervals. These grills can quickly channel rainwater from the road surface into the drainage pipes during rainy days, keeping the roads dry.

Parking lots are also important application scenarios for steel grate grills. Whether indoor or outdoor parking lots, steel grate grills can exert their unique advantages. In indoor parking lots, steel grate grills can be used as floor materials. Their good ventilation and drainage performance can effectively reduce ground dampness and odors, providing car owners with a comfortable parking environment. At the same time, their high-strength feature can withstand the frequent rolling of vehicles, extending the service life of the parking lot floor. In outdoor parking lots, steel grate grills offer excellent anti-slip performance, ensuring the safety of vehicles and pedestrians even on rainy or snowy days.

In the field of industrial buildings, steel grate grills are even more widely applied. In factory workshops, they can be used as work platforms and passage floors, providing workers with a safe and stable working space. Their good ventilation and heat dissipation performance can effectively improve the working environment and enhance work efficiency. For example, in high-temperature workshops such as steel plants and aluminum smelters, steel grate grills can dissipate heat in a timely manner, preventing workers from heatstroke in high-temperature environments. Furthermore, steel grate grills can also be used as guardrails and inspection platforms for industrial equipment, providing guarantees for the safe operation of industrial production.

4. Steel Gully Grid: Durable with Excellent Performance

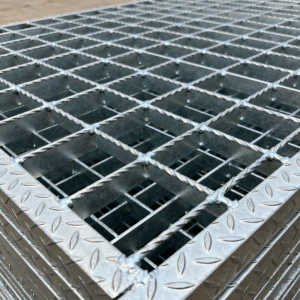

Our steel gully grids, with their outstanding durability, have become a reliable choice for many engineering projects. They are made of high-quality carbon steel or stainless steel, which themselves possess high strength and good toughness, laying a solid foundation for the durability of the steel gully grids.

In terms of manufacturing technology, we adopt advanced hot-dip galvanizing technology. Hot-dip galvanizing involves immersing the steel gully grid in molten zinc liquid, forming a dense zinc layer on its surface. This zinc layer not only effectively isolates air and moisture to prevent the steel from rusting and corrosion but also enhances the wear resistance of the steel gully grid. For example, in some coastal areas, the air has high humidity and salt content, which is highly corrosive to metal materials. Our hot-dip galvanized steel gully grids have been used in these areas for many years and still maintain good performance without obvious corrosion or damage.

In addition, we strictly control the quality during the production process, ensuring that every welding point is firm and reliable, and every detail meets high-standard requirements. This dedication to quality enables our steel gully grids to work stably for a long time in various harsh environments, providing users with reliable guarantees. Whether in high-temperature and high-pressure industrial environments or humid and dusty outdoor environments, our steel gully grids can withstand the test and always maintain the stability and reliability of their performance.

5. Steel Gully Grate: Precise Specifications to Meet Demands

We offer steel gully grates with a wide range of specifications to meet the specific needs of different projects. In terms of flat steel specifications, common widths include 20mm, 25mm, 30mm, 32mm, 35mm, 40mm, 45mm, 50mm, etc., and thicknesses include 3mm, 4mm, 5mm, 6mm, 8mm, etc. Crossbar specifications are also abundant. The cross-sectional side length of twisted square steel is usually 4mm, 5mm, 6mm; the diameter of round steel is commonly 6mm, 8mm, 10mm; and the specifications of flat steel crossbars are similar to those of load-bearing flat steel, such as 20×3mm, 25×3mm.

In terms of spacing settings, common flat steel spacings are 30mm, 40mm, 60mm, and crossbar spacings are mostly 50mm, 100mm. Different specification combinations correspond to different load-bearing capacities and application scenarios. For example, for industrial plant passages with high load-bearing requirements, we usually recommend steel gully grates with a flat steel thickness of 5mm, a spacing of 30mm, and a crossbar spacing of 50mm. This specification can withstand the frequent movement of heavy equipment like forklifts. For places with high requirements for ventilation and lighting, such as drainage ditches in municipal squares, specifications with a flat steel spacing of 60mm and a crossbar spacing of 100mm can be selected to achieve good ventilation and lighting effects while ensuring a certain load-bearing capacity.

In addition, we can also provide customized specification services according to customers’ special needs. No matter how complex the project requirements are, we are confident in providing customers with the most suitable steel gully grate solutions through professional technology and rich experience.

Contact Us!

For more inquiries and questions, kindly contact us for details pls!

Reviews

There are no reviews yet.