Description

Table of Contents

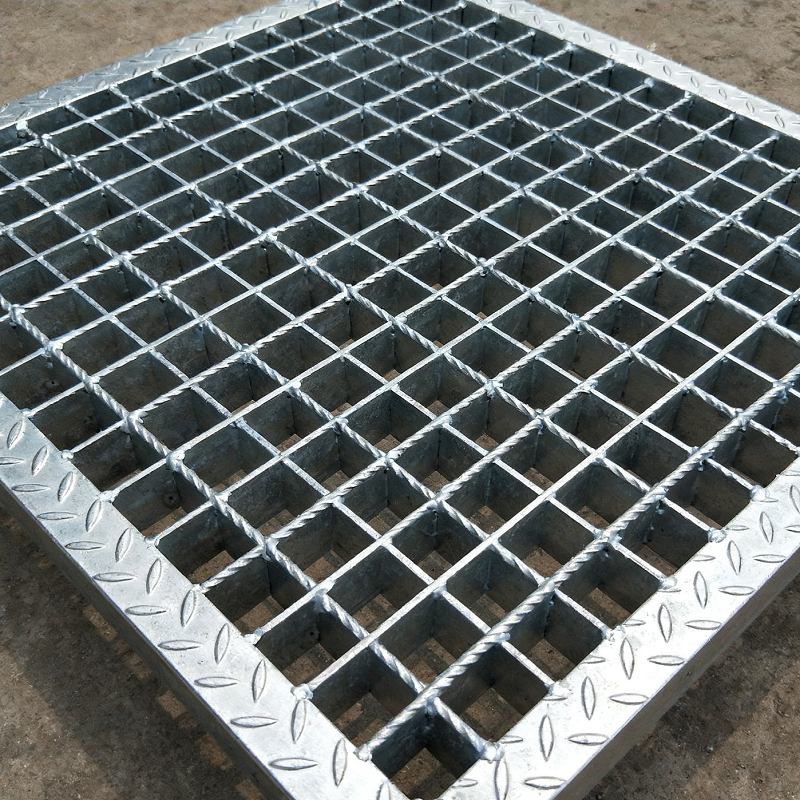

ToggleQuality Steel Grid Plate Grating For Oil Refinery Power & Chemical Plant

Product Specification

| Feature | Details |

|---|---|

| Material | Carbon steel, Stainless steel |

| Type | Flat grating, press lock grating, serrated grating |

| Bearing bar | 20mm, 25mm, 30mm,32mm,38mm, 40mm, 45mm, 50mm ect… |

| Size | as customized |

| Finish | Hot dip galvanized or polished |

1. Superior Material & Structural Design: The Foundation of Reliability

Our Steel Grid Plate are crafted from high-grade carbon steel or stainless steel, selected for their exceptional strength-to-weight ratio and resistance to corrosion, impact, and extreme temperatures—key challenges in industrial settings. The grating features a precision-welded or press-locked structure, with evenly spaced bars that form a stable, open-grid pattern. This design not only minimizes weight (reducing load on supporting structures) but also allows for efficient drainage of liquids, debris, and even chemical spills—essential for maintaining clean and hazard-free areas.

Each Steel Grid Plate undergoes strict quality control, including load-bearing tests and anti-corrosion treatments (such as hot-dip galvanization or epoxy coating). These treatments enhance resistance to oil, chemicals, moisture, and UV rays, ensuring a long service life even in the most demanding industrial environments.

2. Tailored Solutions for Key Industrial Sectors

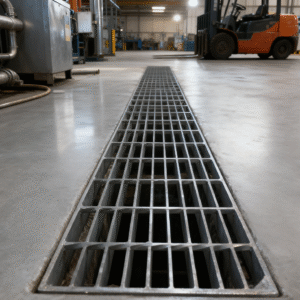

Oil Refinery Walkway: Safety First in High-Risk Zones

Oil refineries require walkways that can withstand constant exposure to oil, solvents, and high temperatures. Our Steel Grating for Oil Refinery walkway is designed with anti-slip surfaces (achieved through serrated bars or textured coatings) to prevent slips and falls, even when wet or contaminated. The open-grid design also eliminates the buildup of flammable materials, reducing fire risks—a critical safety feature in refinery operations. Additionally, the grating’s modular design allows for easy installation and maintenance, minimizing downtime during repairs or upgrades.

Power Plant Structure: Durability for Heavy-Duty Applications

Power plants (including thermal, nuclear, and renewable energy facilities) rely on robust structures to support heavy equipment, pipelines, and personnel. Our Steel Grid Plate is an ideal choice for power plant structure components such as catwalks, platform decks, and stair treads. It can handle high load capacities (ranging from 200kg/m² to over 1000kg/m², depending on specifications) while remaining lightweight, which simplifies transportation and installation. The grating’s resistance to extreme temperatures (from -40°C to 500°C for galvanized models) also makes it suitable for use near boilers, turbines, and other heat-generating equipment.

Chemical Plant Adaptability: Corrosion Resistance at Its Core

Chemical plants expose structural components to aggressive substances like acids, alkalis, and solvents. Our Grating Plates is available in stainless steel (304, 316, or 316L grades) or carbon steel with specialized chemical-resistant coatings, ensuring it remains intact and functional despite constant chemical exposure. The open-grid design further facilitates easy cleaning and inspection, helping plants comply with strict environmental and safety regulations.

3. Compliance & Customization: Meeting Your Exact Needs

All our Steel Grating products comply with international standards, including ISO, ASTM, and DIN, ensuring they meet the safety and performance requirements of global industrial projects. We also offer full customization—from adjusting bar spacing, thickness, and size to choosing specific coatings or materials—to match the unique needs of your oil refinery, power plant, or chemical facility. Whether you need a standard Oil Refinery walkway grating or a custom power plant structure component, our team works closely with you to deliver solutions that align with your project timeline and budget.

In summary, our Quality Steel Grid Plate Grating is more than just a structural product—it’s a long-term investment in safety, durability, and operational efficiency for your industrial facility. With tailored designs for oil refineries, power plants, and chemical plants, we ensure that every component performs reliably, even in the toughest conditions.

Contact Us!

For more inquiries and questions, kindly contact us for details pls!

Reviews

There are no reviews yet.