Description

Table of Contents

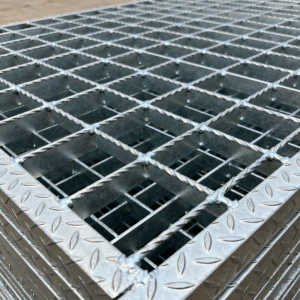

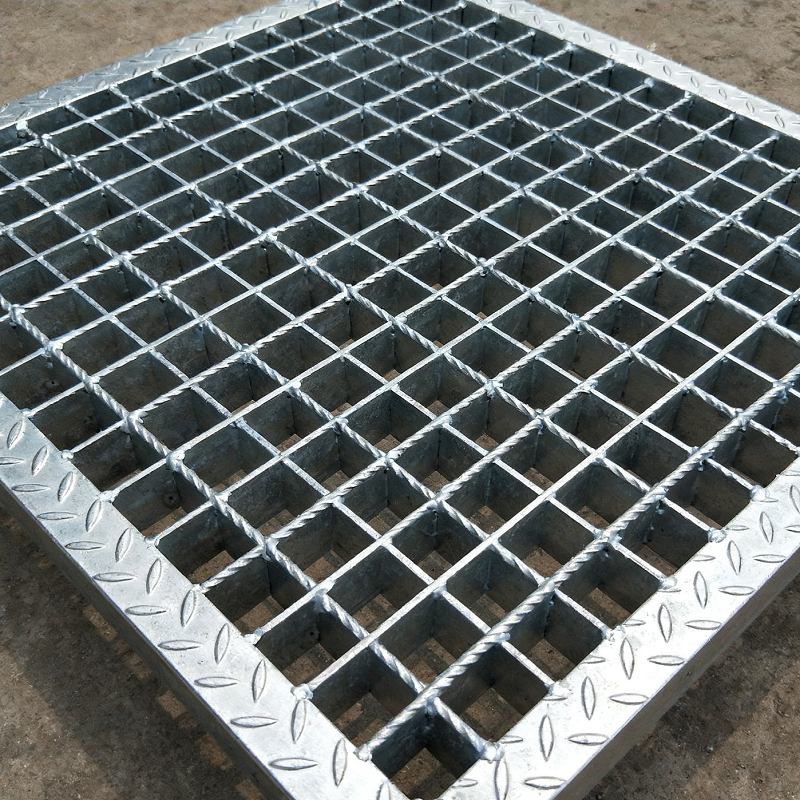

ToggleElectro Welded Drainage Steel Grating With Frame ElectroForged Fabricated Steel Grates

Product Specification

| Feature | Details |

|---|---|

| Material | Carbon steel, Stainless steel |

| Type | Flat grating, press lock grating, serrated grating |

| Bearing bar | 20mm, 25mm, 30mm,32mm,38mm, 40mm, 45mm, 50mm ect… |

| Size | as customized |

| Finish | Hot dip galvanized or polished |

1. Product Overview

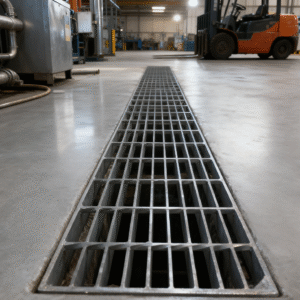

This high-performance steel grating integrates electro welding, electro forging, and fabrication processes to meet industrial and civil drainage needs. Made of quality materials, it ensures efficient water flow, strong load-bearing capacity, and resistance to impacts and harsh environments, reducing maintenance costs and extending drainage system life in urban roads, factories, and public facilities.

2. Key Types of Steel Gratings

2.1 Electro Welded Steel Grating

Manufactured via precise electro-welding, it joins bearing and cross bars with strong, uniform welds for firm structure. Its regular grid boosts drainage, air circulation, and light transmission, while enabling easy, fast installation to save time and labor.

2.2 ElectroForged Steel Grating

Using advanced electro-forging, it enhances steel’s hardness, toughness, and wear resistance. It resists impacts and heavy loads without deformation, with a smooth surface that reduces dirt buildup for easy maintenance.

2.3 Fabricated Steel Grating

Custom-made via cutting, drilling, bending, and assembling, it fits diverse shapes/sizes for specific projects. It ensures high precision to match supporting structures and can combine with frames/handrails for integrated drainage solutions.

2.4 Drainage Steel Grating

Designed with a special grid, its scientifically spaced bars enable quick water flow while blocking debris. Anti-slip surface treatments (serration/raised patterns) reduce slipping risks, and anti-corrosion treatments (hot-dip galvanizing) resist rain/sewage/chemicals.

3. Product Advantages

- High Strength & Durability: Made of carbon/stainless steel, it has excellent tensile/compressive strength to withstand heavy loads and impacts.

- Efficient Drainage: Prevents waterlogging even in heavy rain, ensuring normal operation of roads/plants.

- Strong Corrosion Resistance: Surface treatments (hot-dip galvanizing) extend life in harsh environments like chemical plants.

- Easy Installation & Maintenance: Lightweight, standardized design allows quick installation; smooth surface simplifies cleaning.

4. Application Scenarios

- Urban Infrastructure: Used in roads, squares, and parks for drainage ditches/manholes.—This product is widely used in urban roads, sidewalks, squares, parks, and other public areas.

- Industrial Plants: Applied in workshop floors and sewage areas to withstand equipment loads and corrosion.—In industrial plants such as factories, power plants, chemical plants, and metallurgical plants, the product is used in workshop floors, equipment platforms, drainage channels, and sewage treatment areas

- Transportation Facilities: Installed in highways, airports, and ports for drainage systems.—In transportation facilities such as highways, railways, airports, and ports, the product is used in drainage systems of road shoulders, railway platforms, airport runways, and port yards

- Water Treatment Projects: Used in sedimentation tanks and inspection wells for corrosion resistance and efficient drainage.—In water treatment plants, sewage treatment plants, and water conservancy projects, the product is used in sedimentation tanks, filter tanks, drainage channels, and inspection wells.

5. Customization Services

We provide professional customization services to meet the specific needs of different customers. According to the customer’s project requirements, we can customize the steel grating with different materials (carbon steel, stainless steel), sizes (length, width, thickness), grid spacings, surface treatments (hot – dip galvanizing, cold galvanizing, painting), and additional components (frames, handrails, kick plates). Our professional design team will communicate closely with customers to provide optimized design solutions, ensuring that the product meets the requirements of the project in terms of performance, installation, and cost. Additionally, we have a strict quality control system throughout the production process to ensure that each customized product meets high – quality standards.

Contact Us!

For more inquiries and questions, kindly contact us for details pls!

Reviews

There are no reviews yet.