Description

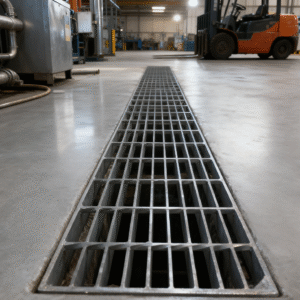

Galvanized Grating Steps and Panels 30mm Bearing bar

Product Description

| Feature | Details |

|---|---|

| Material | Carbon steel, stainless steel |

| Bearing bar | 30x3mm |

| Hole opening | 30x100mm |

| Finish | hot dip galvanized |

| Price | EXW China factory US$22/m² |

Product Description

As an indispensable part of modern architecture and industrial facilities, steel gratings provide safe and convenient passage guarantees for people’s production and daily life with their excellent performance and diverse applications.

From the careful selection of raw materials, to the strict control of processing technology, every link demonstrates the high quality and reliability of steel grating steps.

1. High-Quality Raw Materials, Forging Excellent Quality

Steel grating steps mainly use two types of raw materials: carbon steel and stainless steel.

Carbon steel, such as the common Q235 carbon steel, has high strength and can bear large loads. It is suitable for general industrial environments and places with high load-bearing requirements.

In factory workshops, warehouses and other places with frequent personnel movement and cargo handling, carbon steel steel grating steps can provide stable support to ensure safe use. Stainless steel, especially 304/316 stainless steel, has become the first choice in harsh environments due to its excellent corrosion resistance.

In factory workshops and warehouses, carbon steel grating steps provide stable support to ensure safe use.

In industries such as chemical engineering and marine engineering, the humid and high-salt environment poses a great test to the corrosion resistance of materials.

Stainless steel grating steps can effectively resist corrosion, extend service life, and reduce maintenance costs.

2. Exquisite Processing Technology, Ensuring Structural Stability

(1)Welding Technology

Welding is a key link in the processing of steel grating steps. Manual welding has high flexibility. For steel grating steps with complex structures or special sizes, experienced welders can ensure uniform and firm welds through manual operation. In some customized projects, manual welding can better meet the special needs of customers. Machine pressure welding, on the other hand, has the advantages of high efficiency and precision.

Through high-pressure resistance welding machines, load-bearing flat steel and cross bars can be quickly welded together at a certain spacing to form a solid grid structure. This welding method not only improves production efficiency but also ensures the stability of product quality, enabling steel grating steps to have high load-bearing capacity and good structural stability.

(2)Design of Gratings and Steps

The grid design of steel gratings is carefully calculated to ensure sufficient load-bearing capacity while achieving good ventilation and drainage functions.

The open grid structure allows water, dirt, and other substances to be discharged quickly, avoiding potential safety hazards caused by water accumulation.

The step part is designed according to ergonomic principles, with appropriate width and height. The surface usually adopts anti-slip design, such as serrated flat steel or surface texture treatment, which effectively increases friction, prevents people from slipping, and maintains good anti-slip effect even in humid or greasy environments.

The surface usually adopts an anti-slip design, such as serrated flat steel, effectively increasing friction and preventing slips even in humid or greasy environments.

3. Fine Surface Treatment, Enhancing Durability

Hot-dip galvanizing is a common surface treatment method for steel grating steps. By immersing the steel grating steps in molten zinc liquid, a uniform and dense zinc layer is formed on the surface. This zinc layer can not only effectively isolate air and moisture to prevent steel from rusting and corroding but also has good wear resistance.

Steel grating steps treated with hot-dip galvanizing show a silver-gray luster on the surface, which is beautiful and elegant. At the same time, it greatly improves the durability of the product, enabling it to be used for a long time in harsh environments such as outdoors and humid areas.

4. Wide Applications, Meeting Diverse Needs

Steel grating steps are widely used in various fields.

In the industrial field, stairs, platforms, and passages in factory workshops, warehouses, and mines provide guarantees for workers’ safe passage and cargo transportation.

In the construction field, the use of steel grating steps in stairs, balconies, corridors and other parts of buildings can not only ensure structural safety but also add a sense of modernity to the building. In the field of public facilities, stairs and passages in public transportation places such as subway stations, railway stations and airports have a large flow of people and high requirements for safety and durability.

Steel grating steps can meet the strict requirements of these places with their excellent performance.

To sum up, with its high-quality raw materials and exquisite processing technology, steel grating steps have become an ideal passage solution in modern architecture and industrial facilities.

Whether in industrial environments pursuing safety or in construction projects focusing on aesthetics, steel grating steps demonstrate their unique value.

Whether in industrial environments pursuing safety and stability or in construction projects focusing on aesthetics and practicality, steel grating steps can demonstrate their unique value.

Reviews

There are no reviews yet.