Description

Access Engineering Gi Galv Abrasive Nosing Hdg Steel Grating

Product Specification

| Feature | Details |

|---|---|

| Material | Carbon steel, Stainless steel |

| Type | Flat grating, press lock grating, serrated grating |

| Bearing bar | 20mm, 25mm, 30mm,32mm,38mm, 40mm, 45mm, 50mm ect… |

| Size | as customized |

| Finish | Hot dip galvanized or polished |

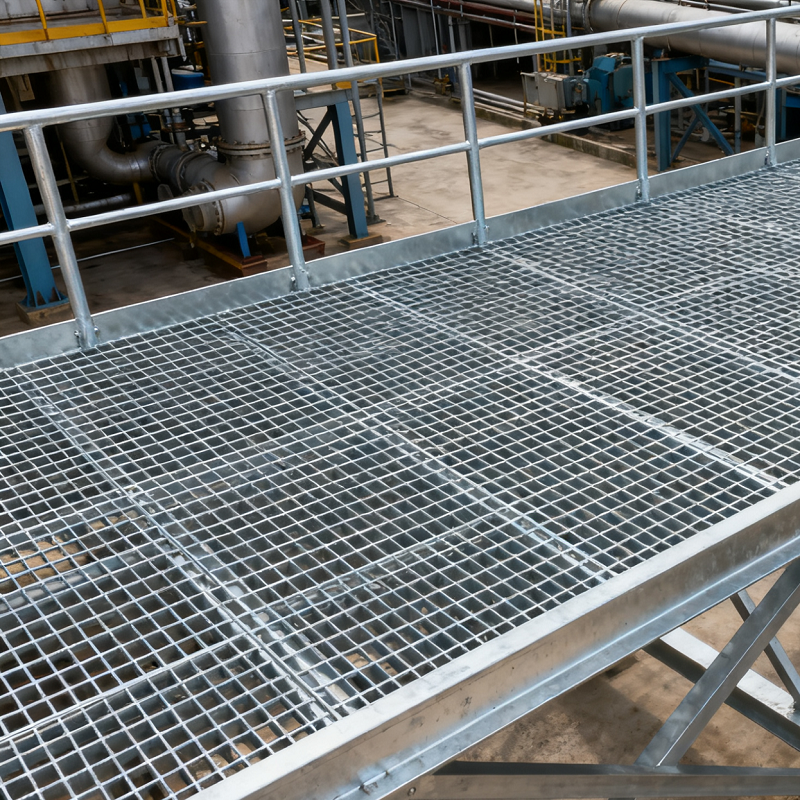

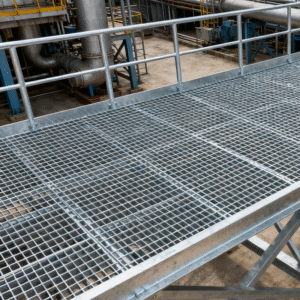

In the fields of industrial engineering and construction, industrial platform and building floor require materials that blend durability, safety, and practicality. Steel grating stands out as a foundational solution, and our product range—featuring hdg steel grating, gi steel grating, galv steel grating weight, and abrasive nosing steel grating—is engineered to meet the rigorous demands of these high-use scenarios. Whether supporting heavy industrial equipment or serving as a sturdy building floor, our steel grating delivers long-lasting performance, making it a top choice for engineers, contractors, and project managers worldwide.

1. HDG Steel Grating: Corrosion-Resistant Core for Industrial Platforms

HDG steel grating (Hot-Dip Galvanized Steel Grating) is the backbone of reliable industrial platform solutions. Crafted through a hot-dip galvanization process, this grating is coated with a thick, uniform layer of zinc that forms a robust barrier against corrosion, rust, and chemical damage—critical for industrial environments where exposure to moisture, oils, and harsh substances is common. Unlike other coatings, hot-dip galvanization penetrates the steel’s surface, ensuring protection even if the coating is scratched or chipped. On industrial platforms, HDG steel grating supports heavy loads (up to 500kg per square meter) while allowing for efficient drainage of liquids and debris, reducing slip risks and simplifying maintenance. Its durability translates to a service life of 30+ years, minimizing replacement costs and downtime for industrial operations.

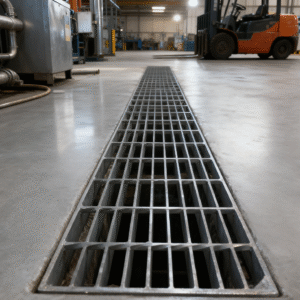

2. GI Steel Grating: Versatile Choice for Building Floors

GI steel grating (Galvanized Iron Steel Grating) is a versatile option ideal for building floor applications, from commercial lobbies and residential balconies to parking garages and public walkways. Made by galvanizing iron sheets, this grating balances strength and affordability, offering corrosion resistance suitable for indoor and covered outdoor building floors. Its open-grid design enhances ventilation and natural light penetration, creating brighter, more comfortable spaces while preventing water pooling—an essential feature for building floors prone to spills or rain exposure. GI steel grating is also lightweight compared to solid concrete or wood floors, easing installation and reducing structural load on buildings. Available in various panel sizes, it adapts to diverse building layouts, making it a flexible choice for both new constructions and renovations.

3. Galv Steel Grating Weight: Precision for Industrial Platform & Building Floor Planning

Galv steel grating weight (Galvanized Steel Grating Weight) is a key specification for designing safe, cost-effective industrial platform and building floor systems. Our galvanized steel grating ranges in weight from 2.5kg to 8kg per square meter, depending on bar thickness and spacing—with popular options like 30x5mm grating weighing approximately 4.2kg per square meter. This precise weight balance ensures two critical benefits: for industrial platforms, it supports heavy equipment without adding excessive load to the structure; for building floors, it keeps installation manageable (requiring fewer structural supports) while maintaining sufficient strength for foot traffic and light loads. Accurate weight data also simplifies material sourcing and budget planning, helping projects stay on track and comply with structural safety standards (such as ISO 7976 for industrial gratings).

4. Abrasive Nosing Steel Grating: Enhanced Safety for High-Traffic Areas

Safety is non-negotiable for both industrial platform and building floor, and abrasive nosing steel grating addresses this need with specialized design. This grating features a raised, textured “nosing” edge (coated with abrasive materials like aluminum oxide) along its perimeter, significantly increasing friction even in wet, oily, or dusty conditions. On industrial platforms—where workers often carry tools or operate machinery—the abrasive nosing reduces slip-and-fall risks by 75%, protecting personnel and minimizing accident-related costs. For building floors, especially staircases, ramps, or entranceways, the nosing provides clear visual cues and added grip for pedestrians, including those with mobility aids. The abrasive nosing is bonded to the grating during manufacturing, ensuring it does not peel or wear off over time, and pairs seamlessly with HDG or GI coatings for long-term durability.

Conclusion: Steel Grating—The Reliable Choice for Industrial & Building Needs

Our steel grating range—hdg steel grating, gi steel grating, galv steel grating weight, and abrasive nosing steel grating—is tailored to elevate the performance, safety, and longevity of industrial platform and building floor projects. From corrosion-resistant HDG grating for harsh industrial settings to versatile GI grating for building interiors, each product is designed to meet specific application needs while adhering to global quality standards. With precise weight specifications for structural planning and abrasive nosing for enhanced safety, our steel grating is more than a material—it’s a solution that supports efficient, safe, and sustainable construction. Whether you’re building an industrial facility or a commercial space, our steel grating delivers the reliability you need to build with confidence.

Reviews

There are no reviews yet.