Description

Table of Contents

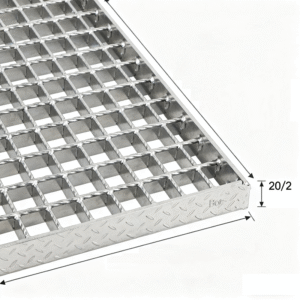

Toggle20/2 44x11mm Compliant Stainless Steel Grating Antislip Borden Banded SS304 316 Material

Product Description

| Feature | Details |

|---|---|

| Material | Carbon steel, stainless steel |

| Bearing bar | 30x3mm |

| Hole opening | 30x100mm |

| Finish | Polishing, hot dip galvanized |

| Price | EXW China factory US$88/m² |

Our stainless steel grating is a high-performance solution designed to meet the strict demands of industrial, commercial, and heavy-duty environments, combining exceptional durability, corrosion resistance, and anti-slip safety. Built with industry-leading 304 and 316 stainless steel alloys, and enhanced by the robust banded steel grating structure and rigorous manufacturing standards, this product delivers long-term reliability and versatility across diverse applications.

304/316 Stainless Steel: Tailored Corrosion Resistance for Every Scenario

The choice of 304 and 316 stainless steel ensures our grating adapts to varying environmental challenges, making it suitable for both general and harsh-condition use.

- 304 Stainless Steel Grating: Ideal for general-purpose scenarios such as factory floors, pedestrian walkways, and indoor platforms. Composed of 18% chromium and 8% nickel, it offers excellent resistance to atmospheric rust, mild chemicals, and daily wear. Its cost-effectiveness and easy maintenance (requiring only occasional wiping with water or neutral detergent) make it a popular choice for projects where moderate corrosion protection is needed—for example, warehouse loading docks or commercial building stair treads.

- 316 Stainless Steel Grating: Engineered for extreme environments, this alloy adds 2-3% molybdenum to the 304 composition, significantly boosting resistance to pitting, crevice corrosion, and saltwater damage. It is the top choice for coastal areas (e.g., marine docks, offshore platforms), chemical processing plants (handling acids or alkalis), and food processing facilities (where frequent sanitization with harsh cleaners is required). Unlike standard metals, 316 stainless steel retains its structural integrity even after years of exposure to moisture, chemicals, or high humidity.

Banded Steel Grating: Reinforced Structure for Maximum Load-Bearing & Safety

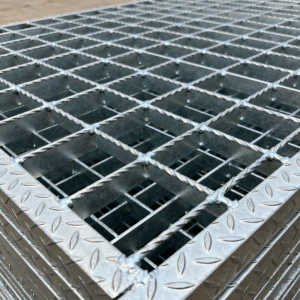

Our banded steel grating features a reinforced edge band (border) design that addresses two key pain points: structural stability and edge safety.Traditional grating often suffers from edge deformation under heavy loads or accidental impacts, but our banded structure uses thickened stainless steel strips (2-3mm thicker than standard slats) welded along the perimeter of each panel. This reinforcement not only increases the grating’s overall load-bearing capacity (supporting up to 500kg/m² for light-duty panels and 1500kg/m² for heavy-duty models) but also eliminates sharp edges, reducing the risk of cuts or tripping in high-traffic areas.Additionally, the grating’s slats and crossbars are precision-manufactured using either press-locking or seamless welding techniques—both compliant with quality standards. Press-locked panels offer higher flexibility for custom sizes, while welded panels provide superior rigidity for heavy machinery zones (e.g., factory equipment platforms). Every joint is inspected to ensure no gaps or loose connections, further enhancing safety and preventing debris accumulation.

International Manufacturing Standards: Ensuring Uniform Quality & Compliance

Our stainless steel grating represents a commitment to strict quality control and global industry compliance.From raw material selection to final inspection, every step follows International standardized process:

- Material Testing: All 304/316 stainless steel coils undergo spectroscopic analysis to verify alloy composition, ensuring they meet ASTM A480/A480M standards for thickness and chemical content.

- Precision Fabrication: Automated cutting machines ensure slat and crossbar dimensions are consistent within ±0.1mm, avoiding uneven spacing that could compromise safety.

- Surface Treatment: Optional anti-slip serrations (depth: 1-1.5mm) are added to slats using abrasive blasting, providing enhanced traction in wet or oily conditions—critical for areas like restaurant kitchens or industrial wash bays.

- Final Inspection: Each panel is checked for flatness (tolerance: ≤2mm/m), weld strength, and corrosion resistance (via salt spray testing), with only passing products receiving the Quality certification mark.

Versatile Applications: From Industrial Sites to Commercial Spaces

Our stainless steel grating (available as both 304/316 and banded models) caters to a wide range of needs:

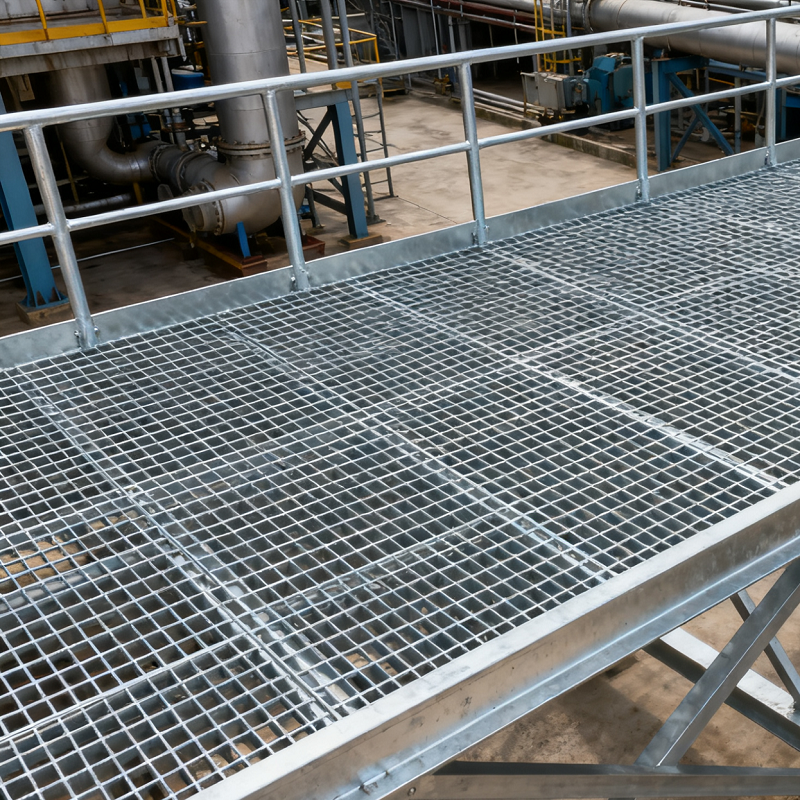

- Industrial: Factory floors, machinery platforms, chemical storage areas, and power plant walkways (316 models preferred for chemical/power sectors).

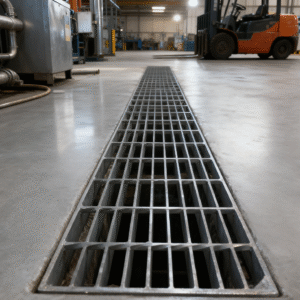

- Commercial: Shopping mall atriums, restaurant kitchen floors, office building staircases, and outdoor terraces (304 models ideal for indoor/outdoor non-harsh environments).

- Specialized: Marine docks, offshore oil rigs, food processing lines, and wastewater treatment plants (316 banded models required for corrosion and load demands).

We also offer customizations, including panel size (from 1m×1m to 3m×6m), slat spacing (10mm-50mm), and edge finishing (smooth or serrated), ensuring the grating fits seamlessly into any project design.

In summary, our stainless steel grating—powered by 304/316 stainless steel, reinforced by banded structure, and guaranteed by standards—combines strength, safety, and adaptability. It is not just a building material, but a long-term investment in durability and operational efficiency.

Reviews

There are no reviews yet.